FIBC BAGS / JUMBO BAGS

We offer extensive range of FIBC / Big Bags /Jumbo Bagsthat are available in various sizes and are offered to various industries such as chemicals, dyes-intermediates, pharmaceuticals, minerals, rubber, sugar etc. These FIBC / Big Bags /Jumbo Bagsare widely appreciated due to attractive specifications.

FIBC/Jumbo bagsbasically have a square or rectangular base. The bagsizes can vary on depending the purpose for which they will be used. For instance, while there are no specific bag sizes for storage, preference might be given to taller and wider bags. Generally, bags meant for shipping or for rail freight have a common size as listed below.

We offer a wide range of fabric in different widths and gram mage; enabling customized supply at any given time. Our fabrics are designed to meet a minimum of 5:1 safety factor. However, denser and stronger fabrics for a safe working load of 6:1 or higher can be manufactured. In bulk bags, working loads range from 500-2000 kg.

What exactly are FIBC bags?

Flexible Intermediate Bulk Containers, sometimes known as FIBCs, are essentially huge bags composed of woven polypropylene. Dry goods are typically transported in or stored using these FIBC bags. They are primarily employed by the food processing and pharmaceutical sectors and are more commonly referred to as “Jumbo bags” by FIBC bags manufacturers .These FIBC bags typically have a weight capacity of between 2000 and 4000 lbs. However, these measurements may vary based on the needs and preferences of the consumer.

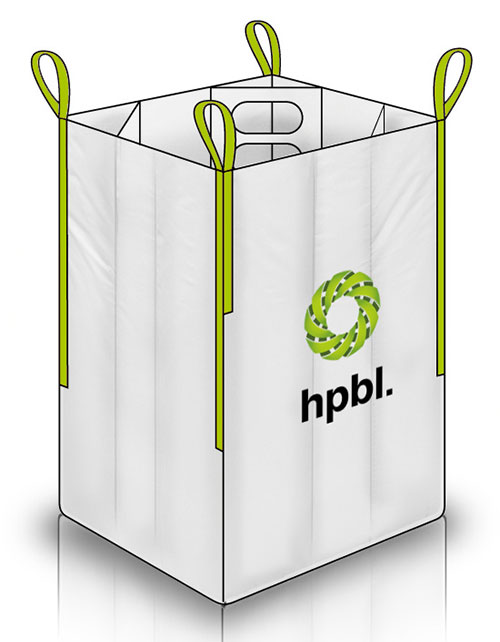

Types of FIBC Bags:

Users of FIBC bags are typically worried about controlling static electricity, which occurs when electric charges are unbalanced within particular materials. Static electricity can build up when these large bags are fully loaded or when they are quickly emptied of fine granules. When packing any kind of combustible or flammable substance, or when combustible dust is likely to be present in the surroundings, it is essential to avoid or eliminate the electrical charge. According to FIBC bags suppliers, FIBC bags are categorized into 4 types which are discussed below

With years of experience in the packaging industry, FIBCO PLASTIC INDUSTRY has gained expertise in producing FIBC bags that cater to various industry needs. They understand the specific characteristics and requirements of each bag type and can provide valuable guidance in selecting the most suitable option. We prioritize customer satisfaction and strive to meet their specific needs. We provide reliable customer support, timely delivery, and excellent service, ensuring a positive experience for our clients.

Selecting FIBCO’s Type A, Type B, Type C, or Type D FIBC bags offers the advantages of superior quality, compliance with industry standards, customization options, expertise, reliable static control, sustainability focus, and customer satisfaction.